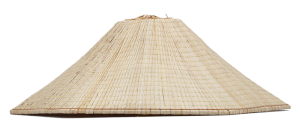

Ko-wn was named after the bright cloud

which block off the sun light -like a Sugegasa.

We only use carefully selected materials to

create the finest Sugegasas with solid techniques.

![]()

Planting:

The process to create the fine Sugegasas starts with planting Suge.

We plant them in fall and they sprout in spring.

They grow taller than us by July.

![]()

Mowing:

Mow Suge in July.

Dry them in the sun. Eventually color fades away.

![]()

Make frames:

Sugegasa's frames are made of bamboo.

They are made by hand work with traditional techniques.

![]()

Sewing:

Attach Suge strips around the frames (which is very complicated process).

Then sew Suge to the frames stitch by stitch.

- Artist

- Ko-wn Nakayama

- Background

- 2015.06 Begun an apprenticeship into the way of inheritor.

- 2018.03 Certified as a Skilled Sugegasa maker of Ecchu Takaoka.

- Award

- 2017.03 Rookie of the Year @Annual Sugegasa Competition (the 3rd) :Koyuki

- 2017.09 Encouragement Prize @Takaoka Craft Competition 2017 :Roppou

- 2018.06 Won a prize @Art Exhibition of Takaoka City (the 24th) :Heisei no Mikurumayama

- 2018.09 Area award @Takaoka Craft Competition 2018 :Sugehimo

![]()

デンサン

【Den-san】

This is the classical Sugegasa called "Tsuno-gasa"(High V shaped ones are called "Tateyama", low V shaped ones are called "Asayama"). Generally used by farmers. The smallest size is 39cm and size varies every 3cm.

六方

【Roppou】

Ko-wn's original Sugegasa. This is the first Hexagon Sugegasa ever made. Top crown of Roppou is also Hexagon shaped and arranged in mutually shifted angles.

平成の御車山

【Heisei no Mikurumayama】

Ko-wn's original Sugegasa. This is one of the flat Sugegasas called "Ichimonji-gasa". "Heisei no Mikurumayama" is the first Octagon shaped "Ichimonji-gasa".

Factory Tour

Want to know how Sugegasas are made? Factory tours are available to companies, organizations and schools, as well as the general public.

Reservations are required. To make reservations, please use the contact form below.

*Your reservation will be confirmed with a contact from us.

Contact us